Stainless Steel Flanges

We have the following flanges types:

Stainless Steel A-315, F-304, Dual grade 304/304L, 316/316L, 304H, 316, 316H, 309, 310, 317L, 321, 347, 347H, 904L, ANSI / ASME 16.5 since 1/2″ to 24″ class 150, 300, 400, 600, 900, 1500, 2500. AWWA C207 since 4″ to 144″ class 2B, 2D, 3D, 4E, 5E, 6F, DIN, JIS, Special Ring and many other special designs.

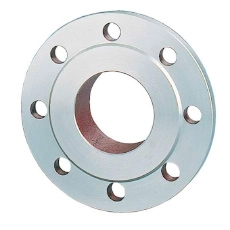

Counter Flange

Flange Slip On

These are type of flanges that slide over the end of piping and then welded in place. These flanges are ideal for lower pressure applications. These are easily fitted and welded into different pipes.

Flange Welding Neck

Weld neck pipe flanges attach to the pipe by welding the pipe to the neck of the pipe flange. Weld neck pipe flanges are often used for high pressure applications. The inside diameter of a weld neck pipe flange is machined to match the inside diameter of the pipe.

Flange Blind

A blind flange is used to close ends of piping systems. It is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed.

Flange Threaded

Threaded flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications. They are the special type of pipe flanges which can be attached to the pipe without welding. Threaded flanges are threaded in the bore which match an external thread on the pipe. These threads are tapered in order to create a seal between the threaded flange and the pipe as the tapers approach the same diameter. Sometimes a seal weld is also used together with the threaded connection.

Flange Socket Weld

Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow.